Building Smarter, Living Better:

Pioneers With Purpose

The Genesis of Modern Fortress

Brought together by their shared vision of transforming the housing market, a dream team of seasoned professionals embarked on a groundbreaking journey.

Drawing from diverse backgrounds in real estate, wealth management, strategic marketing, and eco-friendly construction, our team passionately refined and optimized the approach to using SIPs in home building.

Their mission? To shape a future where every person could live in a high-quality, energy-efficient home, without breaking the bank. And so, Modern Fortress was born.

Fueled by their combined experience, unyielding dedication, and a relentless drive to innovate, this team didn’t just set out to build homes. They set out to make a difference.

Every Modern Fortress home stands as a testament to their ambition – a beacon of change, signaling a new era in affordable, sustainable living.

Join us, as we redefine the norms and usher in a revolution, one home at a time.

Challenging the Status Quo

Unleashing the Power of Hyperformance Panels by BYF

The homebuilding industry is facing rising costs, lengthy timelines, and increased pressure to adopt sustainable practices. Traditional methods can no longer keep up with these demands. But there’s a smarter solution.

Hyperformance Panels by BYF offer an innovative approach, combining affordability, strength, and eco-conscious design. Our pre-engineered, ready-to-install panels slash labor costs and speed up construction while delivering superior energy efficiency and durability.

We’re not just meeting the challenges of today’s housing market; we’re redefining the future of homebuilding with smarter, greener solutions.

Building Smarter, Living Better

Building Smarter, Living Better

Hyperformance Panels by BYF

The Old Way

Traditional Construction

Lengthy due to multiple stages including framing, insulation and exterior work.

Expensive labor costs, separate insulation costs, and subcontracting for various stages.

Bigger crews of framers, insulators, painters, and contractors required.

Separate insulation required, adding to the time and cost.

Complicated steps to complete exterior work.

Substantial training required for each construction phase.

Traditional construction often results in less flexible designs.

Traditional materials can result in lower energy efficiency, increasing both environmental impact and utility costs.

The New Way

Build Your Fortress

Construction time reduced substantially as Hyperformance Panels by BYF arrive fully assembled, ready for immediate installation.

Significant cost savings by streamlining a three-step process into one.

Due to Hyperformance Panels by BYF ready-to-install design, you only need a small crew.

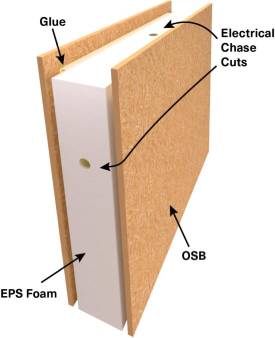

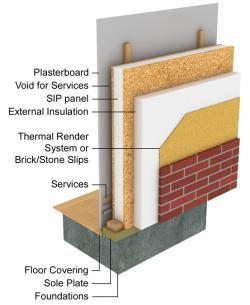

Each panel is expertly designed with integrated insulation for enhanced efficiency.

Your Hyperformance Panels by BYF can be delivered in one of three customizable ways to best suit your project needs.

One all-inclusive training covers all aspects of handling and installing Hyperformance Panels by BYF.

Choose from four customizable designs, tailored to adapt and match homeowner preferences.

Unmatched energy efficiency, thanks to the advanced design of our Hyperformance Panels by BYF.

Building Smarter, Living Better

Building Smarter, Greener, and More

Affordable Homes with Hyperformance Living

At BYF, we're not just manufacturing Hyperformance Panels; we're reshaping the future of housing. Imagine being part of a revolution where every aspect of the process delivers unparalleled advantages. From builders to homeowners, Hyperformance Panels by BYF offer superior energy efficiency, affordability, and sustainability, setting a new standard in modern living.

Builders & Developers

Our Story

You’ll be the proud owners of an exceptional home that doesn’t break the bank, but instead, breaks records in energy efficiency, and where design brilliance is paramount. Experience this unique intersection of artistry and sustainable living.

BYF

Our Process

1. Pick A Design

Choose the home that’s right for you from our four customizable designs.

2. Order

Once you’ve selected your design, simply place your order online. It’s that easy!

3. Production

Our team gets to work, producing your SIPs in our factory using our innovative, efficient process.

4. Quality Check

Each panel undergoes a rigorous quality check to ensure it meets our high standards and receives certification.

5. Delivery

Your panels are securely packaged and delivered to your site for assembly. They’re ready the moment they arrive.

6. Assembly

With pre-fabricated SIPs you can anticipate a quick and efficient building process.

7. Handover

With our certified general contractors you can rest easy knowing your home was built properly trained by professionals.

Hear What Happy Homeowners & Builders

Have to Say About Their Experience

We’re not just building homes, we’re building dreams, one sustainable brick at a time.

-Builder Bob

We’re not just building homes, we’re building dreams, one sustainable brick at a time.

-Builder Bob

We’re not just building homes, we’re building dreams, one sustainable brick at a time.

-Builder Bob

We’re not just building homes, we’re building dreams, one sustainable brick at a time.

-Builder Bob

Have Questions?

We Have Answers.

Hyperformance Homes by BYF are constructed faster than traditional framed buildings. With a well-trained panel installation crew, labor costs can be reduced by up to 60 percent compared to stick framing. At BYF, we manufacture panels as large as 4ft by 24ft, enabling entire walls to be erected swiftly, which also minimizes drying time. Hyperformance Panels by BYF can arrive at the jobsite as ready-to-install components, thus eliminating the need for individual framing, insulating, and sheathing operations of stick-framed walls.

Window openings can be pre-cut into the Hyperformance Panels by BYF, eliminating the need for a separate header depending on the size. In addition, electrical chases are usually incorporated within the core of the panels, removing the necessity to drill through studs for wiring.

Hyperformance Homes by BYF are constructed faster than traditional framed buildings. With a well-trained panel installation crew, labor costs can be reduced by up to 60 percent compared to stick framing. At BYF, we manufacture panels as large as 4ft by 24ft, enabling entire walls to be erected swiftly, which also minimizes drying time. Hyperformance Panels by BYF can arrive at the jobsite as ready-to-install components, thus eliminating the need for individual framing, insulating, and sheathing operations of stick-framed walls.

Window openings can be pre-cut into the Hyperformance Panels by BYF, eliminating the need for a separate header depending on the size. In addition, electrical chases are usually incorporated within the core of the panels, removing the necessity to drill through studs for wiring.

Building Smarter, Living Better

The new American Dream is owning a home built with highly efficient, Hyperformance Panels by BYF

In today’s world, sustainability and efficiency are no longer optional—they're essential. Hyperformance Panels by BYF offer both builders and homeowners the future of construction. Builders benefit from faster, more efficient installations, reducing labor costs and build times. Homeowners enjoy lower heating and cooling bills, superior insulation, and resistance to mold, pests, moisture, and even seismic events.

With a smaller carbon footprint, durable materials, and eco-conscious design, Hyperformance Panels by BYF aren't just sustainable—they're responsible. Invest in the New American Dream today.